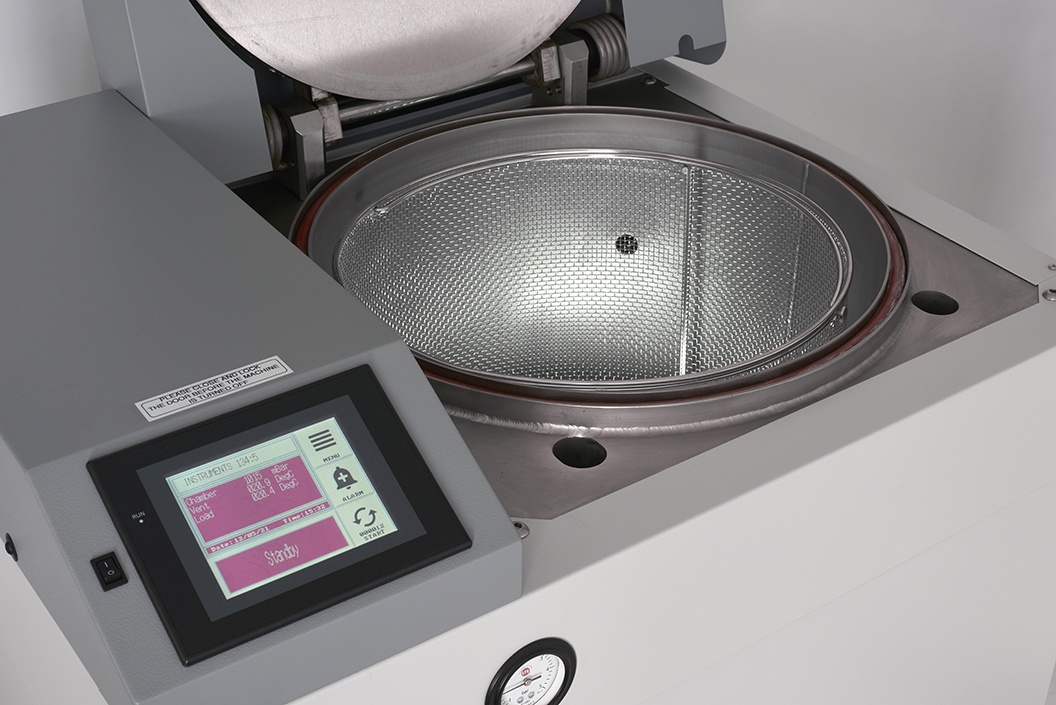

In parts 3 – 4 of our Autoclaves 101 guide, we are going to explain how an autoclave sterilizes.

We already know that depending on the load type, (see Autoclaves 101 – Load Types guide) that different loads use different temperatures and factors for sterilization.

However, the sterilization process itself always follows the same 3 stages: Air removal, Sterilization and Cooling/Drying.

Sterilization itself requires specific criteria to be met. Firstly, air removal. All autoclaves have a method for removing air from the chamber and load, and there is good reason for this. Air is an insulator of heat, so air pockets in or around the load can cause cold spots, thus preventing the correct conditions for effective sterilization of the whole load.

In addition, the steam needs to be saturated with water droplets at 5% by mass thus creating the perfect sterilizing environment. Air pockets can have an adverse effect on efficacy, which is why air removal is so important.

For certain loads such as hazardous Lab waste/discard or porous load autoclaves the air removal stage is critical. Effective air removal allows the items requiring sterilization to come into full contact with the saturated steam leaving them completely sterile and safe for use or discarding. For some loads such as fluids or general discard, air removal, whilst important, may not be as critical.

There are currently 3 methods of Air removal utilised by steam autoclaves. The first is steam purging, also sometimes known as downward displacement air removal. This is normally a timed sequence, so that as the autoclave admits/raises steam and heats above 80°C, a small exhaust valve opens, and it effectively pushes the air from the chamber. Our Touchclave-R autoclaves use this method as standard. As this method is more passive by nature the average cycle times for each load will be greater than if you were to utilise the other methods.

Method 2 is positive pulsing. Positive pulsing offers an improvement to standard steam purging by intermittently opening and closing the exhaust valve at set intervals. This helps to stabilise the chamber pressure temporarily, building up the steam volume before opening and pushing the steam in and the air out more forcefully. Positive pulsing will help improve cycle speeds in comparison to the steam purge and comes as standard on our Touchclave-K autoclaves.

Method 3, vacuum air removal is the most effective and most popular option with many benefits including even shorter cycle times, and a post-sterilizing vacuum sequence which can provide enhanced drying of the load (or total drying where vacuum is combined with a steam jacket). A deep vacuum is necessary on Porous Load sterilizers due to the nature of the items being sterilized, with many being wrapped instruments, therefore vacuum removal is the only way to truly remove all air and achieve a sterile load.

Fitting a vacuum pump to the machine allows the vacuum to create a negative pressure in the chamber which enables faster introduction of steam to the chamber. This works by pulling a deep vacuum within the chamber (vacuum levels will depend on the type of vacuum pump being used – liquid ring pumps are the most effective), before then injecting the steam, raising the pressure back up to just below atmospheric then puling another deep vacuum. This ‘pulsed vacuum’ process is repeated a number of times (depending on the load type) to achieve a very effective air removal. On porous load machines as used in CSSD’s, an air detector is fitted which can accurately detect whether any air remains in the chamber. If any air remains, then the cycle will result in error and fail.

Following negative vacuum pulsing, positive pulsing can also take place which allows fast and effective penetration of steam deep into the load; steam will be forced into the chamber up to just below sterilizing pressure (2500mbA) before releasing the steam once more to a chamber pressure of (1200mbA). This process Is repeated a number of times (again depending on the load) to ensure complete air removal/steam penetration and therefore a successful sterilization stage.