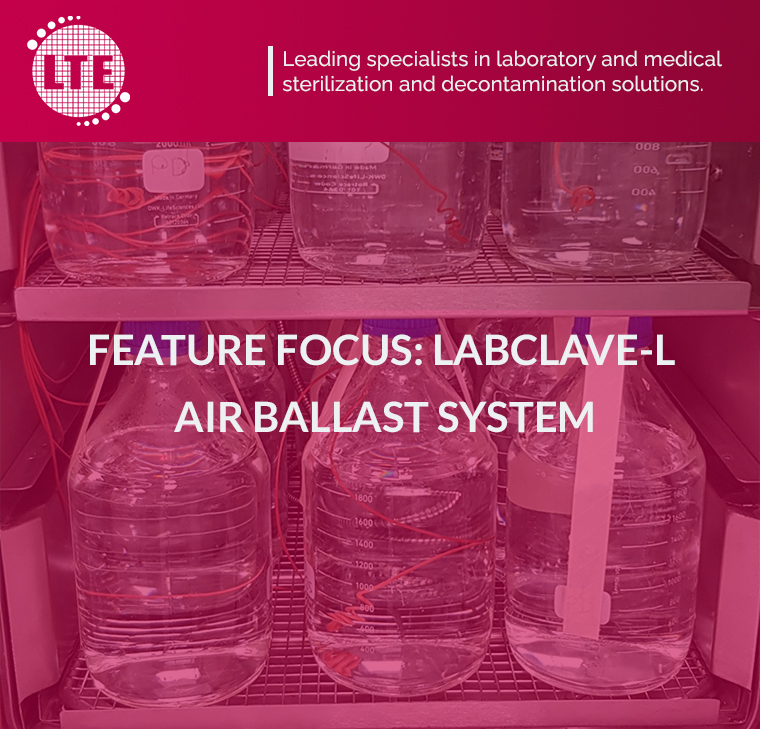

How the Labclave-L Autoclave for Media Sterilisation Enhances Liquid Load Safety and Efficiency

When it comes to sterilising liquids safely in a busy laboratory environment, choosing the right equipment is critical. The new Labclave-L autoclave for media sterilisation has been designed with performance, reliability, and load protection in mind, particularly when handling delicate liquid loads in bottles, flasks, or tubes.

A key innovation in the Labclave-L is the inclusion of air ballast technology as a standard feature, a system that enables precise pressure-control during the cooling phase. This feature offers clear benefits when working with liquids and culture media, both in terms of safety and operational efficiency.

Why choose the Labclave-L Autoclave for Media Sterilisation?

Sterilising culture media and liquid solutions is a fundamental process in many laboratories, but it comes with challenges, especially when dealing with sealed or partially sealed containers. Without the right control measures in place, there’s a risk of boil over, glass breakage, or incomplete sterilisation.

The Labclave-L with its built-in air ballast system offers a dedicated solution for this task, ensuring consistent results and reduced handling risks with every cycle.

The Role of Air Ballast in a Liquid Load Autoclave

Air ballast works by introducing controlled compressed air into the chamber just before the cooling stage begins. This controlled pressure is essential for managing the behaviour of liquids during the natural drop in temperature and pressure after sterilisation.

In a lab autoclave with air ballast, the system:

- Maintains internal chamber pressure as temperatures fall

- Prevents rapid pressure drops that could trigger flash boiling

- Ensures containers remain sealed and intact

- Prevents volume loss of media loads

This makes it ideal for laboratories looking to prevent boil over in autoclaves and avoid bottle breakage during sterilisation, two common risks when processing liquid media.

Efficiency Gains Through Safer Liquid Sterilisation

Traditional autoclaves without air ballast often require much longer cooling periods or manual interventions, slowing down turnaround time significantly and increasing the chance of load failure.

The Labclave-L with its air ballast system, by comparison, delivers:

- Shorter cycle times due to faster, controlled cooling

- Greater energy efficiency from more stable cycle management

- Improved safety for lab staff, with reduced risk of spillage, breakages or thermal injury

These benefits make the Labclave-L a robust choice for labs needing a reliable liquid load autoclave that supports both safety and productivity.

Designed for Laboratories That Rely on Precision

Whether you’re sterilising nutrient broth, agar media, buffer solutions or other aqueous materials, the Labclave-L is engineered to make the process seamless and repeatable. It combines pressure-controlled autoclaving with intuitive controls and high build quality, ensuring it meets the daily demands of modern laboratories.

In Summary

The Labclave-L stands out as a high-performance autoclave for media sterilisation, optimised for liquid loads through the integration of advanced air ballast technology. For laboratories seeking to sterilise liquids safely, avoid breakage, and increase throughput, this autoclave delivers confidence and consistency.