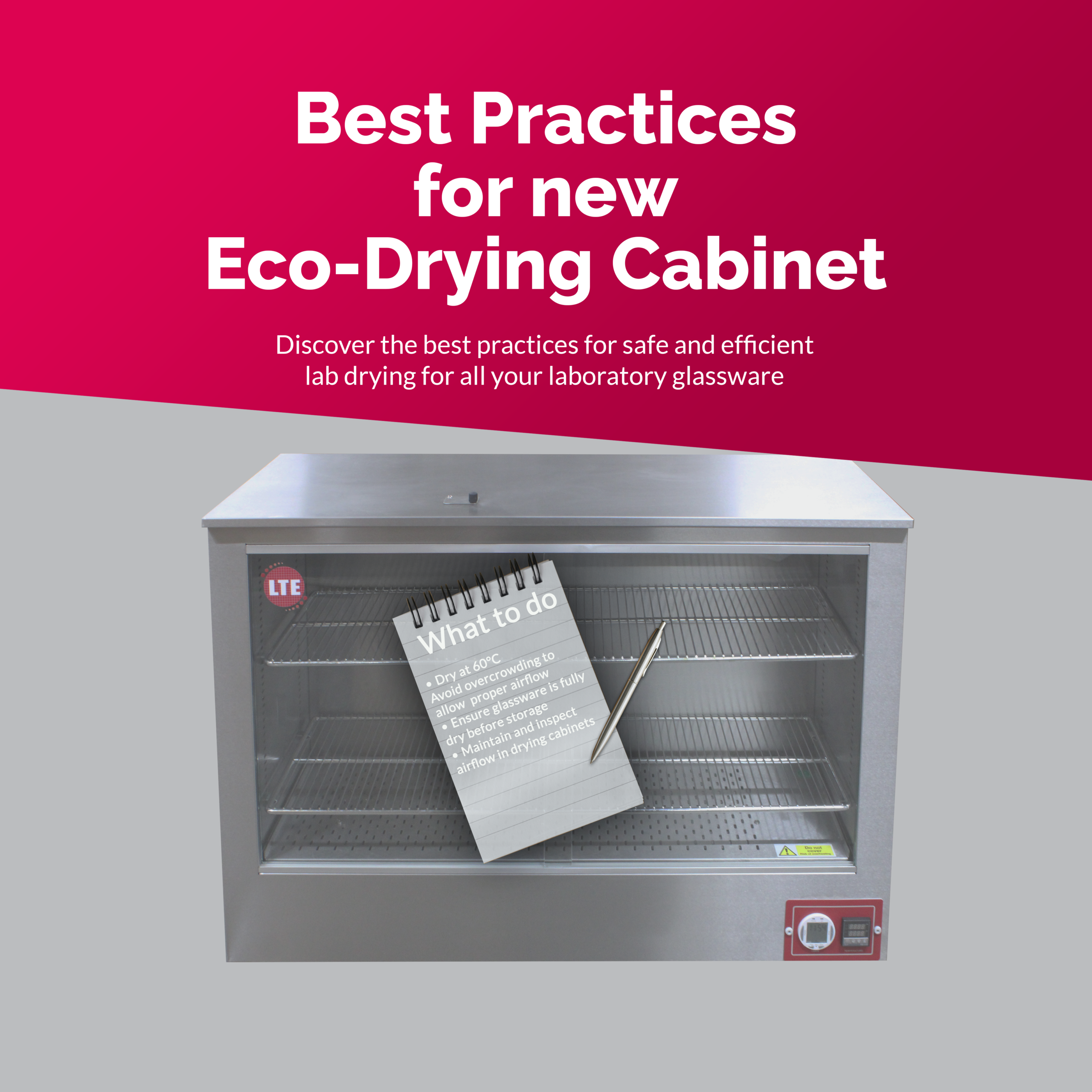

Glassware Drying Cabinet: Best Practices for Safe and Efficient Lab Drying

Glassware drying cabinets play a vital role in removing moisture from laboratory glassware, instruments, and other equipment. Our new Eco-Drying range not only delivers reliable, high quality drying performance but also provides up to 65% energy savings compared to standard glassware drying cabinets.

Importance of Drying Glassware in Laboratories

In laboratories, even the slightest trace of moisture or bacteria on glassware, can compromise sterility, disrupt workflows, and undermine the accuracy and consistency of results. Drying cabinets are essential in laboratories across fields such as forensics, medicine, and scientific research, where rapid glassware turnover and precise outcomes are critical.

Risks of Residual Moisture and Microbial Contamination

Residual moisture in glassware can promote the growth of bacteria, molds, and yeasts, potentially contaminating future samples and compromising experimental results. The Eco-Drying Cabinet eliminates residual moisture, preventing microbial growth. Its digital temperature controller allows users to accurately

Glassware drying cabinets play a vital role in removing moisture from laboratory glassware, instruments, and other equipment. Our new Eco-Drying range not only delivers reliable, high quality drying performance but also provides up to 65% energy savings compared to standard glassware drying cabinets.

Importance of Drying Glassware in Laboratories

In laboratories, even the slightest trace of moisture or bacteria on glassware, can compromise sterility, disrupt workflows, and undermine the accuracy and consistency of results. Drying cabinets are essential in laboratories across fields such as forensics, medicine, and scientific research, where rapid glassware turnover and precise outcomes are critical.

Risks of Residual Moisture and Microbial Contamination

Residual moisture in glassware can promote the growth of bacteria, molds, and yeasts, potentially contaminating future samples and compromising experimental results. The Eco-Drying Cabinet eliminates residual moisture, preventing microbial growth. Its digital temperature controller allows users to accurately set and monitor drying conditions, ensuring glassware and other items are thoroughly dried. By removing all moisture, the cabinet supports consistent, high-quality laboratory outcomes.

How Water Spots Affect Lab Results

Water spots may seem harmless, but in a laboratory setting they can compromise the accuracy and reliability of results. Residual mineral deposits left behind by incomplete drying can affect sample preparation, interfere with analytical instruments, and undermine sensitive procedures. The Eco-Drying Cabinet prevents the formation of water spots, helping laboratories maintain the highest standards of cleanliness and precision.

Common Issues with Traditional or Older Drying Cabinets

Inconsistencies in drying performance can often occur with traditional or older drying cabinets. In forced-air models, faulty fans or uneven airflow can lead to inconsistent temperatures, resulting in incomplete drying or even over-drying. Older systems may also suffer from poor temperature regulation and insufficient heat output, preventing glassware from being fully sterilised.

Recommended Temperatures and Proper Loading

For precision drying, temperature control is critical, with temperatures around 60°C recognised as optimal for most laboratory glassware. Overcrowding should also be avoided to ensure air circulates freely allowing each item to dry and sterilise properly. Operating at this moderate temperature not only achieves effective drying but also reduces energy consumption, supporting eco-friendly laboratory practices, reducing energy consumption in line with green laboratory initiatives. In contrast, higher temperatures of around 100°C increase the risk of thermal stress and micro-fractures in glassware, potentially shortening its usable lifespan.

Energy-Efficient and Eco-Friendly Drying Practices

Explore the Eco-Drying Cabinet today and experience how superior drying performance can streamline workflows, improve reliability, and support a more energy-efficient laboratory environment.

Best Practices Checklist for Laboratory Drying Cabinets

- Avoid overcrowding to allow proper air circulation

- Maintain controlled temperatures around 60°C for optimal drying

- Regularly clean the cabinet to prevent microbial buildup

- Inspect fans and airflow in older or forced-air models

- Ensure glassware is fully dried before storage or reuse

FAQs

Q: Why is drying lab glassware important?

A: Proper drying prevents microbial contamination, ensures accuracy in experiments, and maintains sterility of equipment.

Q: What temperature is optimal for drying glassware?

A: Temperatures around 60°C are recommended for most laboratory glassware, balancing effective drying with protection against thermal stress.

Q: How can a drying cabinet prevent microbial growth?

A: By removing all residual moisture and providing controlled temperature drying, a cabinet eliminates the environment microbes need to grow.

Q: Are energy-efficient cabinets as reliable as standard models?

A: Yes, modern energy-efficient drying cabinets maintain precise temperature control and airflow, delivering the same high-quality drying performance while reducing energy use.